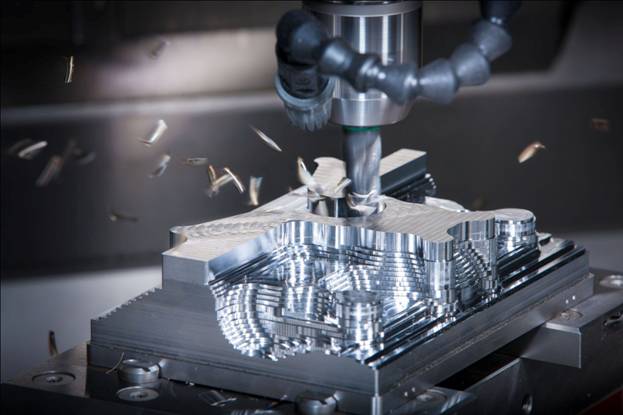

CNC machining, also known as Computer Numerical Control

machining, is a manufacturing process commonly used in some manufacturing

industries. These computer control machines have replaced the traditional

centre lathes, vertical millers, routers, and shaping machines.

CNC manufacturing is an industrial manufacturing

concept that supports the automation of industrial machines in the performance

of specific tasks controlled by instructions fed to the machine. There are many

benefits associated with the use of CNC machines in manufacturing. Because of

these advantages, most manufacturing companies have completely replaced

traditional machine equipment with computer numerical control machinery.

Here is how CNC machines can benefit your manufacturing

processes.

CNC machines save on the cost of

manufacturing

When you automate your industrial process with CNC machines,

you ensure you make full use of all your raw materials. This is thanks to the

accuracy of CNC machines, which significantly reduces waste. With this machine,

you can cut on losses and increase the productivity of your company.

CNC machines are safer

A CNC

machine’s fabrication process is completely automated. Therefore, a machine

operator is not needed for the production process. This ensures that the CNC

machine working environment is safe. This is because it can work without the

need for supervision or interference from human workers. Sometimes, a

manufacturing process can involve handling complicated and highly dangerous

materials like steel or metal. Without CNC machining, the possibility of

workplace accidents is higher. CNC machines are highly accurate and thus rarely

pose a safety risk.

Increase in the speed of production

Computer numerical control (CNC) machining is a very efficient process. For this reason, using the CNC machine in a manufacturing process reduces the number of steps included in the process of creating a specific part. This means that CNC machining allows you to create multiple parts in a day than it would be possible when using traditional production processes. It also ensures that you use less time to produce these parts.

Increase in production efficiency

In terms of speed, CNC machined work faster than human

workers and do not require breaks. You can significantly improve production

efficiency by allowing the machine to run throughout the night, long after

human workers have gone home.

When it comes to designing parts, CNC machines are considered

to be the most efficient systems for the job. Most computer numerical control

machines come equipped with inbuilt measures for quality assurance protection.

This makes it possible for the CNC machine to detect when there is an error in

the production process. Whenever there is an issue, the machine halts its

functions to protect its components from further errors. If possible, a CNC

machine can solve a problem without the need for hardware repairs. This ensures

that there is minimal downtime during production.

CNC machines help to save on overhead

CNC machines can be left unattended for hours or days without

needing the attention of an operator. This allows your employees to focus on

other areas of production. This improves employee satisfaction since the

machine tends to repetitive, boring tasks. In turn, you will experience an

increase in employee productivity. If you are working on a tight budget, a CNC

machine is an excellent way of reducing the number of operators you need in

your company. With a smaller number of human workers, you nor only save on

company overhead, but you also increase safety.

CNC machines deliver the same

results

Even with the most experienced human workers, it is

impossible to get the same quality finishing for parts. This is because humans

are prone to errors when they are tired and bored from doing the same task all

day. With a CNC machine, you are sure of the same results in terms of the

quality of the finished product. This is an essential aspect if you manufacture

interchangeable and standardized parts where one defect can render an entire

line of parts unsellable.

With all these benefits, it is clear that CNC machines are

important to any manufacturing plant. Even though other machines can boost

production, CNC machines outweigh all the competition because of their

efficient and reliable technology.